How 3D printing and regenerative medicine work & the impact on veterinary medicine

Guest blog: Regenerative medicine and 3D printing, the future of veterinary medicine

So, what is 3D printing and how is it the future of veterinary medicine? I get asked this question a lot. I'm a licensed veterinary technician (CVT) and research associate at the Louisiana School of Veterinary Medicine. I work for an orthopedic surgeon that created our laboratory of 3D printing and regenerative medicine. Our lab works with existing departments at the vet school and other main campus departments, specifically the engineering department, and we collaborate locally outside of the school. It's a lot of science, all in the name of saving animals!

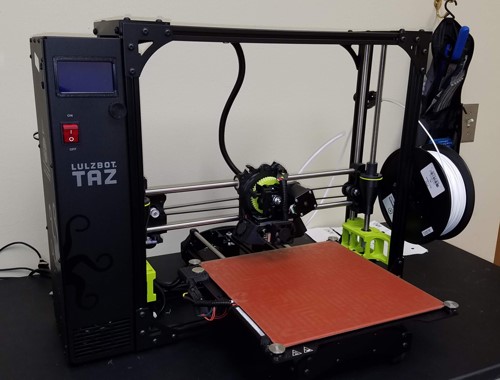

We design and create structures with our lab’s multiple 3D printers and bioprinter. These structures can be formed with either medical grade or generic plastic material called filaments and are specifically created for animals that are injured or in need of an alternative approach to surgery. We recently started working with our new bioprinter, which allows us to create cells out of a gel matrix type of material. This is extremely exciting work because it allows us to collaborate with other researchers in helping us mimic tumor cells. In doing so, new drug therapies can be developed and used for testing. By using 3D printers and bioprinters, we are paving the way for alternative approaches to improving animal health that have not traditionally been offered.

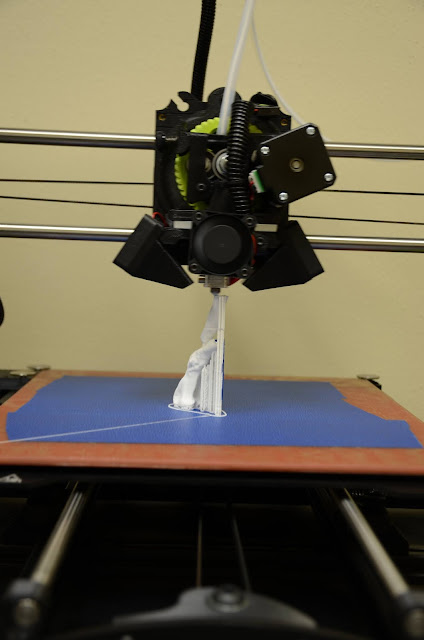

If you're unfamiliar with 3D printing, a 3D printer is a machine with a tiny nozzle that moves along an axis, creating a structure on its platform, otherwise known as the bed. It uses a certain type of plastic filament (usually PLA or ABS) and melts it down at an extremely high temperature to make the structure we designed. We tell the printer what to make using a program on our computer, kind of like when we tell a dog to sit, except our printer always listens. It all begins with an idea that we want to design, and we use our computer-aided design software known as CAD to create whatever we want. Once we finish designing our model, we save it as a stereolithography (STL) file and transfer it over to another program, which is known as slicing software program. We typically use Cura or Raise 3D, but there are many other brands on the market. Once in this software, we make minor edits, including size adjustments and auto-corrections before saving it on our USB drive. We plug the USB drive into our 3D printer, press a few buttons and then our print begins!

Depending on the size of our print, it can take anywhere from a few minutes to a few hours for printing to be completed. We also have the power on our slicer program to make our print a draft print or professional print, which also affects the time of each design. Often, our patients will need a customary design, for example, a cast for a broken limb. To do this we use our 3D scanner, which captures an image of our patient's affected area. We are then able to upload that image into the CAD software, where we can manipulate it and transfer it to our slicer program so that it can be printed. This approach is used in cases where people might not be able to afford surgery for their pet or if their pet is not a good surgical candidate. When these types of cases are seen, our surgery department will offer this as an option. This is a very short description of how the process is done but believe me, it's very time and labor-intensive. A lot of detail goes into our prints so we can make the best quality products for our patients.

The use of 3D printers is slowly catching on within the departments of our hospital and with our clients. With each case, we aim to better improve our designs. Although there are many projects we are working on, we are currently trying to improve the mechanics of our customary designs. One of the biggest problems we face is the flexibility and comfort of our cast designs. Since our patients can't tell us if their cast is comfortable or not, we must solve those problems ahead of time. This means choosing the best type of filament to design a cast and possibly adding support within the cast structure for physical ease.

As we aim to improve, one thing is for sure; using this method of 3D printing provides owners with a less expensive option to surgery. Unfortunately, pet insurance does not cover this accommodation. The upside is that this procedure can cut the time of recovering in half. With surgery, anesthesia is involved, including pre-and post-medications. In many cases, physical therapy is needed afterward. By using our alternative, it negates all these additives and usually spikes the interest in clients, and is less invasive. As with any procedure, there is always the possibility for it not to work for a patient and routine surgery would then be recommended.

As we continue to improve our designs, we look forward to increasing our clientele both within and outside of our hospital and improving the lives of more animals. You can view updates on our current projects and accomplishments on our webpage. We look forward to our upcoming projects; after all 3D printing is the future of veterinary medicine.

Give me a high paw and follow Paws For Reaction on Pinterest

Like Paws for Reaction on Facebook

Follow @PawsForReaction on Twitter

Follow my blog and subscribe in the sidebar >>

1 Comentarios

Your article contains lots of wonderful information about Animal Medicine. Yes, this blog is very helpful. Thank you for sharing such a good article here. Online Medical Supplies For Animals

ReplyDelete